|

|

A newly cleaned air duct system will run more efficiently than a dirty one, resulting in lower utility bills, and a cleaner, less dusty home. More importantly, clean air ducts can have a significant positive impact on your family’s health. Dirty duct systems are a major source of indoor air pollution. Airborne contaminants are pulled into the ducts every time the heating and cooling system runs.

Over time, these contaminants build up inside the ductwork, creating an ideal breeding ground for mold, bacteria, fungi and other microbes. Particles drawn into the air ducts also pass through fiberglass filters and infiltrate into HVAC equipment, undermining the performance and energy efficiency of these systems. This can lead to higher repair and maintenance costs, and shorter service life in the long run. According to the EPA, a build-up of only 0.42" of dirt on a heating or cooling coil can decrease efficiency by 21%. EPA does not recommend that the air ducts be cleaned routinely. |

|

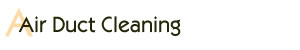

Coil Cleaning

As the dirt and grime collect on the coils it restricts heat transfer causing the compressor to work harder. This adds more heat to the system and raises the head pressure as much as 75%. Higher head pressure can result in a loss of up to 30% of the system’s cooling capacity. This loss will be most noticeable on the HOTTEST DAYS when cooling is needed the most! |

||

|

| 770-885-7665 | 2012 All Rights Reserved | Powered by: |

Additionally coil cleaning provides energy savings by increasing air flow and reducing stress on the HVAC system and in turn reduces the amount of energy needed to operate a system. When a coil becomes fouled with dirt and grime, it cannot provide adequate or designed heat transfer causing higher discharge pressures. The higher discharge pressure requires more electricity, thereby, increasing the costs for operating the equipment. The energy consumption of equipment operating with dirty coils can be as much as 37% more than that used by equipment with clean coils.

Additionally coil cleaning provides energy savings by increasing air flow and reducing stress on the HVAC system and in turn reduces the amount of energy needed to operate a system. When a coil becomes fouled with dirt and grime, it cannot provide adequate or designed heat transfer causing higher discharge pressures. The higher discharge pressure requires more electricity, thereby, increasing the costs for operating the equipment. The energy consumption of equipment operating with dirty coils can be as much as 37% more than that used by equipment with clean coils.